Abstract

Nigeria is a major producer, importer and consumer of rice in Africa. The country produces and milled about 60% 0f the quantity of rice being consumed by its citizens. Otukpo Local Government Area of Benue State is a significant producer of paddy rice in the North-Central Zone of Nigeria but unfortunately, the rice marketers were faced with a major problem of lack of access to credit and high cost of transportation The study examined the comparative economic analysis of rice processing methods in Otukpo Local Government Area of Benue State, Nigeria. Specifically, the study examines the socio-economic characteristics of respondents in the study area, estimate the costs and returns in processing rice; determines the marketing efficiency index of rice processors, describes the operations of the modern and traditional rice processing systems and identify the major factors militating against the modern rice processing methods. The study used primary data which were collected through structured questionnaires oral interviews. Five (5) districts were randomly selected, and a total of 115 rice processors/marketers were randomly selected from twenty (20) villages across the selected districts consisting 60 marketers using modern rice processing methods and 55 marketers using traditional rice processing method. The data were analyzed using descriptive statistics, gross margin and cobb-Douglas production model. The result of the descriptive analysis showed that the modern rice processors were dominated (75.0%) by male while the traditional were dominated (91%) by female. Majority (97%) of the respondents were literate with various levels of education attainment and are within economically productive age bracket. The gross margin for the modern rice processors was N25900.00 per 100kg of rice higher than the traditional rice processing method with N18600 per 100kg of rice. An average net income of N24600 and N18494.8 per100kg paddy rice was obtained for modern and traditional rice processors/marketers, with an average rate of return of 0.3 and 0.20, respectively implying that for every N1.00 invested, N0.32 (32kobo) and N0.21 (21kobo) was realized in the modern and traditional method, respectively. The marketing efficiency index in the modern and traditional rice processing methods were 4.03 and 4.20, respectively indicating that a profit of N4.03 and N4.20 was made from every one Naira spent on the marketing process. The milling capacity of the modern rice processing was 200 kg/min. as against 50 kg/min. in the traditional methods. The study identified lack of awareness, low capital, poor infrastructure, and lack of skilled technical workers as factors militating on the adoption of the modern methods. The study recommended that the government should subsidize the cost of modern technology equipment to enable processors replace their spoiled parts to put back their equipment to work and boost their business.

Keywords: Comparative, Economic, Analysis, Rice, Processing, Benue State

DOI: 10.36349/zamijoh.2025.v03i02.011

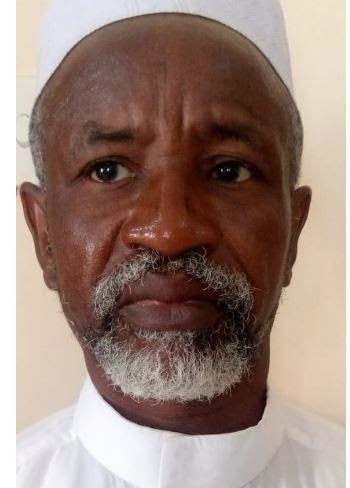

author/Okpeke, G.A., Ogebe O.F. & Adu, V.M.

journal/Zamfara IJOH Vol. 3, Issue 2